Diamonds Don’t Cut?

By Jim Palmer, Marketing Manager – Diamond Products Limited

When using diamond blades for ‘cutting’ concrete, you must know that you aren’t really cutting. In terms of a concrete cutter, spinning a diamond blade into concrete and making a straight line would be considered a cut line. In reality, the diamond blade isn’t slicing through the concrete as in a ‘cut’; it is grinding the concrete away. Understanding the difference gives you insight into how a diamond blade works.

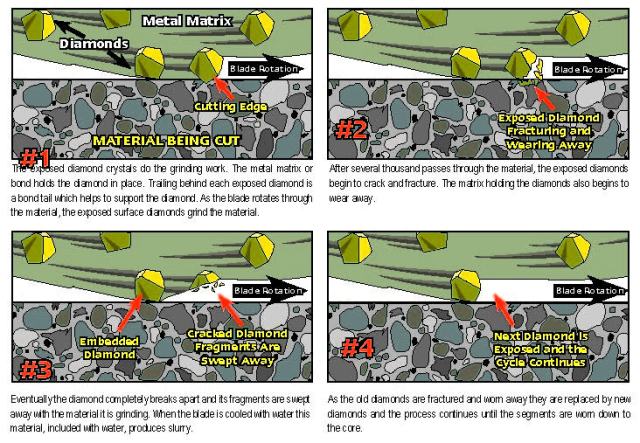

A diamond blade is made up of a steel core, and the diamond impregnated segments that are attached to the edge of the core. The method of attaching these segments vary, depending on the application and purpose. The segments can be laser-welded, silver brazed and vacuum-bonded to the steel core. The diamond segments are made up of a metal bond or matrix that holds the diamond crystals. For the diamonds to grind, they need to have an exposed edge. It is at this exposed edge that the magic happens.

Diamond Process

As this process continues, a line is formed, giving you a ‘cut’ in the concrete. The word ‘cut’ is defined as an opening made by slicing with something sharp. Technically, the edge of the diamond can be considered sharp, but the action is abrading or grinding away the material.

It is important that water is used in the process. The right amount of water mixed with the ground concrete from the action creates a slurry. This slurry helps the process of diamond exposure by acting as an abrasive which wears away the metal matrix that holds the diamonds, thus exposing new diamond edges after the fragmented diamonds are swept away.

The metal matrix or bond is just as important as the diamond itself. The matrix is made up of many different metal powders heated at a high temperature to create the segment. The diamonds are included in the baking process. Softer metals allow the segment to wear away in something harder like concrete. This is ideal, so the diamonds are constantly being exposed. Using harder metals for a hard bond that holds the diamonds in longer is ideal for softer material like asphalt.

Whichever term you choose to call the process, the goal is a nice, straight line created by a violent application of grinding, wearing, and repeating.